A workstation is a convenient surface for workers to put together components, perform repairs, and conduct other important functions of their job. Often, distributors and manufacturers alike often talk about workstations and workbenches as if they were the exact same thing. In fact, in this article, we will also be using both terms. Read More…

Our workbenches come in a variety of styles including ergonomic height adjustable, chemical resistant, ball transfer surface, computer stations, laminar flow stations and more.

As a workstation manufacturer, Pro-Line offers industrial furnishing that increases employee productivity through creating an improved employee work environment.

Formaspace manufactures custom technical furniture, accessories, and services. It develops elegant, practical, flexible solutions for customers in laboratory, technical, drafting, material handling, and industrial environments.

Rousseau manufactures versatile workstations that simplify the user's job while increasing operator efficiency and productivity. The workstations feature an extensive choice of accessories so they can adapt and evolve with your needs. From modular to industrial, we can customize each workstation to your specifications.

Formaspace manufactures custom office and laboratory furniture at scale. Large or small projects with applications for any space. With over 40 years’ experience, our projects range from Life Sciences, to education, office and industrial. Let us be the expert from the highly technical to the fairly straightforward, indoor to outdoor, front to back of house. Made in America using locally sourced...

More Work Station Manufacturers

Workstations

A workstation is a convenient surface for workers to put together components, perform repairs, and conduct other important functions of their job. Often, distributors and manufacturers alike often talk about workstations and workbenches as if they were the exact same thing. In fact, in this article, we will also be using both terms.

Technically, they do have different meanings. Generally, the term “workstation” encompasses an entire workspace with all its components, such as assembly tables, chairs, storage benches, racks, laminar flow benches, clean room work benches, and office tables. While “workbench” can also refer to a complete unit, it more commonly denotes the work surface areas like assembly tables, storage tables, and lab work tables, rather than the entire setup including furniture. It’s important to note that, in this context, workbenches and workstations do not include benches used for woodworking and hobbyist activities. Additionally, in the broader commercial and manufacturing communities, “workstations” typically refer to one of three things: a) combined home/school/office workplace furniture and computer workstations, b) CPU holders and furniture, or c) computers and computer systems that provide a software “work station” for IT administrators.

Applications

Workstations are versatile tools used across various settings, each serving different purposes. Their general applications include enhancing organization and accessibility, reducing worker stress, providing adequate work surfaces in offices and factories, and preventing injuries.

Due to their broad utility and effectiveness, workstations are popular across many industries. Some of the most common applications include:

- Industrial Manufacturing: Workstations are crucial in assembly lines, offering designated areas for specific tasks. They often come equipped with tools, fixtures, and conveyors to streamline production and optimize workflow.

- Shipping and Packaging: Workstations assist with sorting, labeling, and packaging goods. They often feature ergonomic designs and accessories to boost productivity and reduce the risk of repetitive strain injuries.

- Office and IT Environments: Typically configured as office desks with computers, monitors, keyboards, and other accessories, these workstations provide a comfortable and organized workspace for administrative tasks, data entry, programming, and more.

- Cleanroom Research and Laboratories: Specialized workstations are essential in maintaining controlled and sterile environments. They are designed with materials and features that minimize particle contamination, ensuring the integrity of experiments and research processes.

- Education: In classrooms, computer labs, and research facilities, workstations facilitate learning activities, computer-based tasks, and collaborative projects, providing students and educators with dedicated spaces for study and creation.

- Medical and Laboratory Fields: Workstations are vital for tasks such as data analysis, specimen handling, and equipment operation. They are designed to meet specific industry regulations and safety standards, promoting precision and accuracy.

- Engineering and Drafting: These workstations cater to professionals involved in designing, drafting, and modeling. They are equipped with powerful computers, specialized software, and ergonomic features to support complex tasks and enhance productivity.

- Software Development: Programmers and developers use workstations for coding, debugging, and testing software applications. These setups often include multiple monitors, high-performance processors, and ample memory for resource-intensive tasks.

- Automotive Industry: Workstations facilitate vehicle assembly, repair, and maintenance. They may include specialized tools, vehicle lifts, and diagnostic equipment to ensure efficient and safe operations.

- Foodservice Industry: Workstations in commercial kitchens are designed for food preparation, cooking, and serving. They typically feature stainless steel surfaces, storage compartments, and easy-to-clean materials to maintain hygiene and organization.

These examples highlight how workstations are tailored to meet the specific requirements of various industries, optimizing work areas for diverse tasks and ensuring productivity, efficiency, and safety across different professional domains.

History

Workstations and workbenches stem from the basic idea of a table, making it hard to pinpoint their exact origins. However, by 50 A.D., we know that Romans were using simple, low-to-the-ground workbenches where workers usually sat. Significant developments in workbenches did not appear again until the 17th and 18th centuries when the French introduced the “French workbench,” which held pieces in place with stops rather than screws or welding.

Before the Industrial Revolution, workstations were mainly used for woodworking, food preparation, and other artisan crafts. After the Industrial Revolution, they began to evolve for manufacturing and machinery purposes. In the 20th century, workstations have progressed to become more ergonomic and desk-like, designed for worker convenience and efficiency.

Types

Packaging Table

A packaging table, also called a packing table, provides workers with a dedicated space to prepare packages for shipment or distribution without the need to lift or push heavy objects. Equipped with various components and accessories, this table is designed to enhance workflow speed and efficiency while ensuring safety.

Modular Workstation

A modular workstation consists of interlocking components that can be easily arranged and rearranged to meet various needs. Designed for convenience, these workstations typically feature adjustable shelving, bins, and other elements to help organize the workspace efficiently. Among the different types of workstations, modular ones are most commonly used as cubicles due to their versatility in fitting into any space.

Mobile Workstation

Mobile workstations, also known as mobile workbenches, are designed with wheels to allow users to easily move them around a room or throughout a building. They are equipped with braking mechanisms for safety and convenience. Apart from their mobility, these workstations can offer the same level of complexity and features as stationary models.

Industrial Workstation

An industrial workbench is a durable table designed for use in industrial environments, such as manufacturing and repair facilities. Its purpose is to provide a safe and efficient workspace for workers. These workbenches typically include adjustable shelves and drawers for storing tools and supplies. Constructed for heavy-duty tasks, they are usually built with a welded frame made of steel or stainless steel.

Heavy Duty Workbench

A heavy-duty workbench is robust and long-lasting, designed for demanding applications that need a table of its strength. Similar to an industrial workbench, it can be equipped to hold tools and equipment. Often, heavy-duty benches form the “bench” part of industrial workstations. They are widely used in environments such as metal fabrication plants, commercial workspaces, woodworking stores, machine shops, welding facilities, and auto repair shops. Due to their exceptional durability, these workbenches can support objects weighing thousands of pounds without bending or breaking.

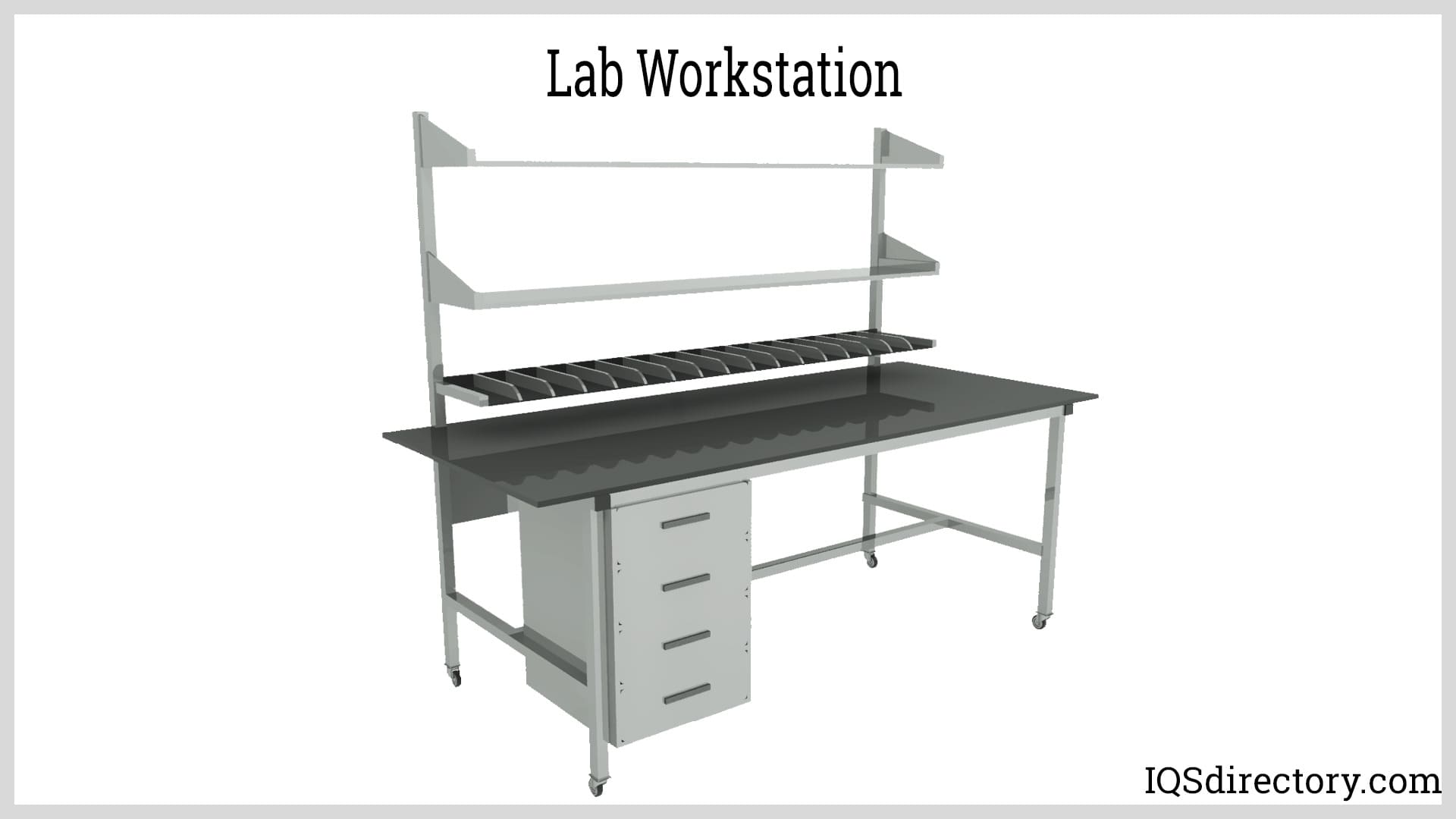

Laboratory Workbench

Lab workbenches are specialized tables used in laboratories. They provide surfaces for various applications such as equipment storage, chemical and biological testing, and student workstations. Due to potential exposure to volatile chemicals and moisture, the tops of these benches are typically made from inert materials. Additionally, they often include components like gas valves, fume hoods, and stainless steel sinks.

Computer Workbench

The term “computer workbenches” broadly encompasses workstations designed to hold computers, computer equipment, and accessories. These workbenches are commonly used at home as PC and laptop stations, as well as in office settings.

Command Operating Center

A command operating center resembles a computer workbench but is more intricate. Commonly used in the field of information technology, these centers are designed to accommodate various items such as computer and electronic equipment, keyboards, processors, and display monitors. The primary objective is to ensure all this equipment is easily accessible.

Equipment Components

Workstations are composed of a work table and several useful components, including drawers and shelves that can be freestanding, bottom-mounted, adjustable on top, or pull-out. In offices or industrial settings with computers, workstations often feature CPU holders to secure and protect the computers. Additional common components of workstations include overhead and under-shelf lighting, electrical outlets and power strips, surge protectors, locks, shelf reels, handles, locking casters, footrests, privacy panels, keyboard trays, and powered back guards.

Benefits

Effective design and utilization of workstations bring numerous benefits across various industries. Here are some key advantages:

Enhanced Productivity

Workstations are crafted to streamline workflow and efficiency. With dedicated, organized spaces, workers can easily access tools, equipment, and resources needed for their tasks. This minimizes time spent searching for materials, promoting focused and productive work.

Improved Ergonomics

Ergonomics plays a crucial role in workstation design. Features like adjustable chairs, ergonomic keyboards, and properly placed monitors encourage comfortable and healthy working postures. Ergonomically designed workstations reduce the risk of musculoskeletal injuries and enhance overall well-being, thereby boosting productivity by reducing discomfort and fatigue.

Tailored to Task Requirements

Workstations can be tailored to meet the unique needs of different tasks and industries. They can include specialized equipment, tools, and accessories essential for specific job functions. This customization ensures workers have the necessary resources readily available, enhancing efficiency and accuracy.

Organization and Space Optimization

Designated work areas help maintain an organized and clutter-free workspace. With proper storage options, tools and materials are easily accessible and storable, reducing the time spent searching for items. An organized workstation also promotes a safer work environment by minimizing the risk of accidents or misplaced items.

Flexibility and Adaptability

Workstations can be designed for adaptability, accommodating changing needs and technological advancements. Features like adjustable height, modular components, and flexible layouts allow workstations to evolve with task requirements, ensuring long-term usability and cost-effectiveness.

Safety and Compliance

Industries with specific safety and regulatory requirements benefit from workstations designed to meet these standards. For instance, in cleanrooms or laboratories, workstations constructed with appropriate materials ensure compliance with cleanliness and contamination control standards, maintaining the integrity of sensitive processes.

Collaboration and Communication

Workstations can foster collaboration and communication among team members. In office settings, shared workstations or open-plan layouts facilitate interaction and idea exchange, promoting teamwork and creativity. Integrated technology solutions like shared displays or collaborative software further enhance communication and collaborative efforts.

Overall, workstations offer increased productivity, improved ergonomics, task-specific customization, organization, adaptability, safety compliance, and enhanced collaboration. By providing optimized work environments, workstations contribute to greater efficiency, employee satisfaction, and overall effectiveness across various industries.

How to Use Them

Using a workbench might seem simple: you sit in front of it, work on your computer, store items in its drawers, and place machines on top for use. However, each workstation has unique details. Here are some tips to maximize productivity and create an ergonomic and efficient work environment:

Maintain Proper Posture

Sit upright with your back supported by the chair and keep your feet flat on the floor or a footrest. Ensure your knees are at a 90-degree angle and your elbows are close to your body. Adjust the chair height, backrest, and armrests for a comfortable and neutral posture.

Position the Monitor

Place the monitor directly in front of you at eye level. Adjust the height and tilt to avoid straining your neck or eyes. Keep the monitor about an arm’s length away from your eyes.

Arrange Tools and Equipment

Keep frequently used tools, such as pens, notepads, and reference materials, within easy reach. Organize them on your desk or in storage compartments to reduce clutter and improve efficiency.

Utilize Ergonomic Accessories

Use ergonomic accessories to enhance comfort and reduce strain. Consider an ergonomic keyboard, mouse, wrist rest, or adjustable monitor stand. Choose accessories that support natural body positions to lower the risk of repetitive strain injuries.

Take Regular Breaks

Take short breaks throughout the day to rest your eyes, stretch your muscles, and refresh your mind. Stand up, move around, and do simple stretching exercises to prevent stiffness and boost blood circulation.

Keep the Workstation Clean and Organized

Clean your workstation regularly to maintain a tidy and organized space. Reduce unnecessary clutter and manage cables properly to avoid tripping hazards.

Customize to Your Needs

Adjust the workstation setup based on your specific needs and tasks. Consider the nature of your work, the tools you use, and any personal preferences or ergonomic needs. Personalizing your workstation can greatly improve comfort and efficiency.

Use Proper Lighting

Ensure your workstation is well-lit to avoid eye strain and fatigue. If possible, use natural light, supplemented with task lighting, to provide adequate illumination for your work area.

Practice Good Workstation Habits

Avoid prolonged sitting by incorporating movement throughout the day. Take short walks or perform stretching exercises. Maintain good work habits, such as prioritizing tasks, minimizing distractions, and using time management techniques to stay focused and productive.

Seek Professional Advice

If you have specific ergonomic concerns or requirements, consult with an ergonomic specialist or occupational health professional. They can offer personalized recommendations and assessments to optimize your workstation setup.

By following these tips, you can create a productive, comfortable, and ergonomic workstation that promotes well-being, reduces the risk of injuries, and enhances overall work performance.

Design and Customization

Workbench manufacturers employ various construction methods, such as partial welding, full welding, or modular assembly. For maximum strength, they prefer partial or full welding, and they may use laser welding technology for enhanced precision. Modular, on-site assembly is ideal for lighter-duty applications.

Industrial workbenches are commonly made from steel or other metals for durability and strength, typically featuring a steel frame. However, very small or light-duty workbenches can be made from heavy-duty plastic. Depending on the specific application, manufacturers offer a variety of workbench top materials, including HDPE, stainless steel, edge-grained maple, composite resin wood, epoxy resin, PVC-edged laminate, self-edged laminate, electrostatic dissipative (ESD) laminate, and chemical-resistant laminate.

No matter the application, suppliers design custom workstations with ergonomics in mind to reduce stress and boost productivity. They tailor customizations based on specific needs and requirements. For instance, adjustable workbenches can accommodate employees with different height requirements. In many cases, the height of workbenches, desks, chairs, and drawers or cabinets can be adjusted to suit the user. Manufacturers can also design workbenches to fit in corners and produce workstations in virtually any size. To enhance durability and protection, they may add paint or a sealant coating.

Safety and Compliance Standards

Safety and compliance standards for workstations vary across industries but generally aim to ensure a safe and healthy work environment for employees. These considerations often involve ergonomic design principles, fire safety measures, electrical safety standards, and adherence to relevant health and safety regulations. Compliance standards may include guidelines for load capacity, stability, and structural integrity of workstations. In specialized industries like cleanrooms or laboratories, additional standards such as contamination control measures, hazardous material handling protocols, and proper ventilation systems may be required. It is essential to consult local regulations, industry-specific guidelines, and relevant safety authorities to ensure that workstations meet the necessary safety and compliance standards for the particular industry and work environment.

Paying attention to safety and compliance standards is crucial to avoid accidents or inadequate support. For instance, if you plan on using heavy amounts of electricity, ensure that your outlets are IEC or NEC certified. If your workbench will be used in food preparation or a medical setting, the surface material should be FDA certified and antimicrobial. For military parts assembly or testing, your workstations need to meet Mil-Specs. Additionally, to ensure worker comfort and safety, your workstations should be OSHA certified. For more specific advice, discuss your needs with your workstation supplier.

Things to Consider

Before purchasing a workstation, it’s essential to understand your specific needs. Consider the following questions: What load capacity do I require? Do I need a special surface? (If you’re working with chemicals, food, or medical instruments, the answer is likely yes.) What are the dimensions of the space where I plan to place my workstation? What is my budget? When do I need the workstation? Is it for sitting, standing, or both? Does it need to be mobile? Once you have answers to these questions, you’re ready to begin your search.

When it comes to purchasing a workstation, you’ll find a vast array of options. While having many choices can be great, it can also lead to information overload, making it difficult to decide. Plus, with so many options, how do you know which ones are of good quality? To help you narrow down your choices, we’ve compiled a list of several leading workstation companies. Each company offers something unique. Start by reviewing their profiles to see which ones have the right combination of products, services, and prices for you. Then, select three or four companies to contact directly. Discuss your specifications with their representatives, compare their quotes, and choose the one that best fits your needs. It’s that simple. Happy hunting!

Choosing the Right Workstation Manufacturer

To achieve the best results when purchasing workstations, it’s helpful to compare multiple manufacturers using our directory. Each manufacturer has a business profile page that showcases their expertise and capabilities, along with a contact form for direct communication to obtain more information or request a quote. Use our patented website previewer to easily review each company’s specialties. Finally, use our streamlined RFQ form to contact several workstation businesses simultaneously with the same request.

55 Gallon Drums

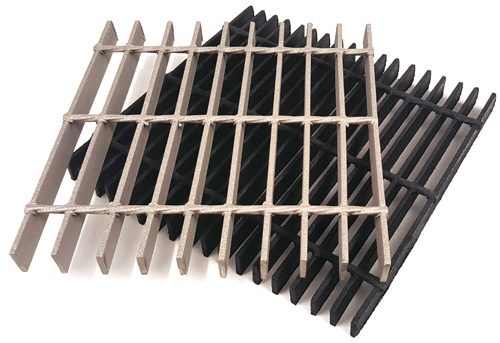

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services