Manufacturers usually build metal workbenches using stainless steel because of its anti-corrosive qualities. Stainless steel creates a rigid frame and gives the workbench a finished look. Stainless steel is also very easy to clean if the bench is being used in a setting where cleanliness is important. Read More…

Our workbenches come in a variety of styles including ergonomic height adjustable, chemical resistant, ball transfer surface, computer stations, laminar flow stations and more.

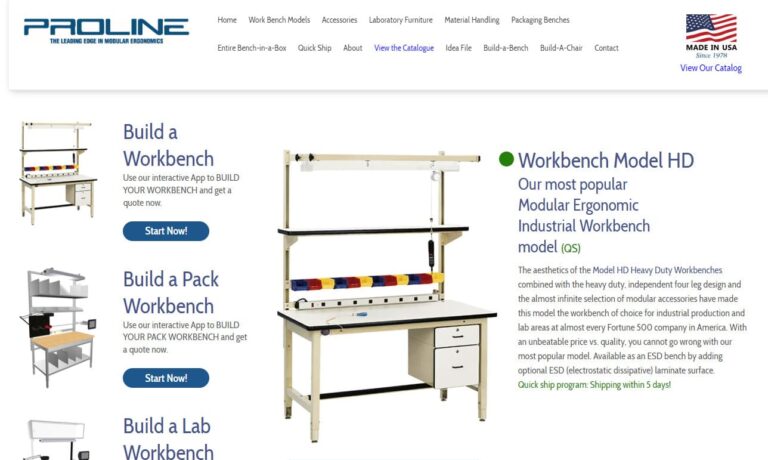

As a workstation manufacturer, Pro-Line offers industrial furnishing that increases employee productivity through creating an improved employee work environment.

Formaspace manufactures custom technical furniture, accessories, and services. It develops elegant, practical, flexible solutions for customers in laboratory, technical, drafting, material handling, and industrial environments.

Rousseau manufactures versatile workstations that simplify the user's job while increasing operator efficiency and productivity. The workstations feature an extensive choice of accessories so they can adapt and evolve with your needs. From modular to industrial, we can customize each workstation to your specifications.

Formaspace manufactures custom office and laboratory furniture at scale. Large or small projects with applications for any space. With over 40 years’ experience, our projects range from Life Sciences, to education, office and industrial. Let us be the expert from the highly technical to the fairly straightforward, indoor to outdoor, front to back of house. Made in America using locally sourced...

More Steel Workbench Manufacturers

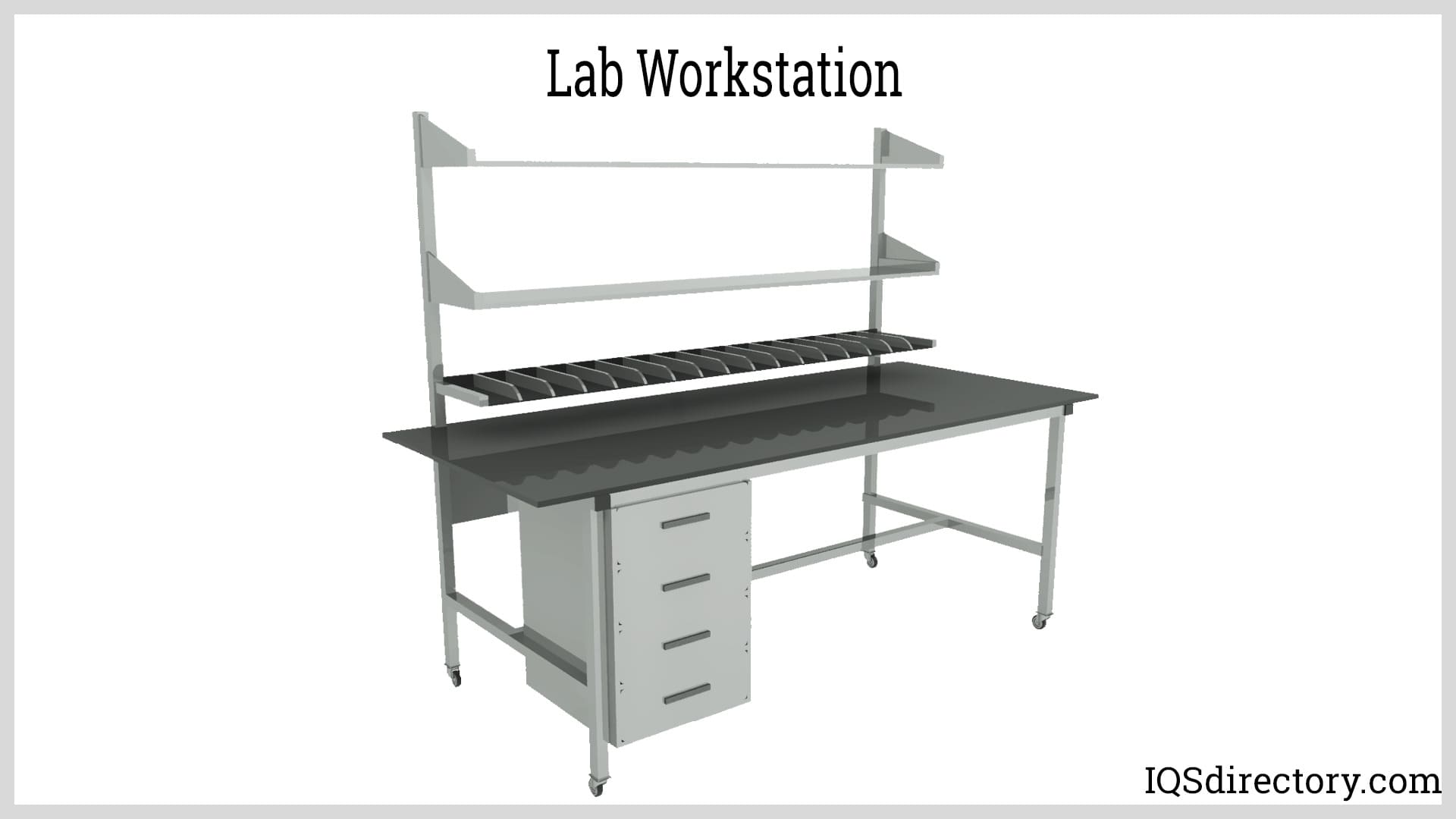

A steel workbench can be used for many purposes; so many different designs exist to help with various functions.

Some steel workbenches can fold up for easy storage when they are not being used. Others have small caster wheels on the legs to make them mobile.

Manufacturing of steel workbenches typically starts in metal fabrication plant where the steel sheets are cut down to size and shaped into the parts of the workbench. They are shaped either by heating the steel and setting it using a mold, or bending it into shape with a cold press process.

Once the pieces have been shaped, they are carefully welded together by hand or by an automated welding machine. Automated welding machines are usually used because they are faster and more precise, allowing for efficient, top quality welds. Proper welding of all the joints on the steel frame is important for the workbench's strength, especially if it is expected to bear a lot of weight.

A steel workbench can be very simple, but it is usually fitted with a few accessories for convenience. Shelving, cabinet doors, and drawers can all be built into the frame for storage and quick access to tools when the workbench is being used. Locks can be fitted to these drawers to secure valuables.

Sometimes overhead lights or extra electrical outlets are integrated into the design of a steel workbench to make things more visible and make it very easy to connect power tools to an electrical outlet.

Most workbench manufacturers design and create a wide variety of steel workbench products that start with the most basic type and move all the way up to a unit that is loaded with extra features. Each industry has different needs, so customers need options when they go to buy a workbench.

55 Gallon Drums

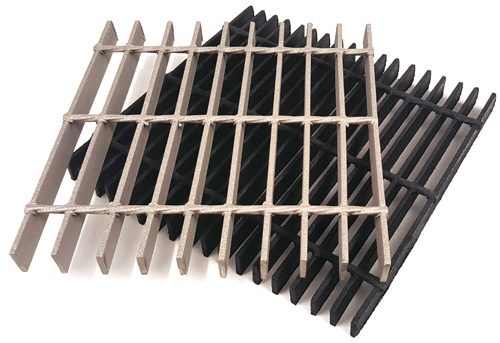

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services